When thinking of building structures of any type, we tend to think of using concrete and steel first right? Why? It’s because that’s what we’ve been taught in the last century. It’s tough, durable, and reliable. Right? Well, there’s a somewhat new player around now, and it looks like it can be be stronger, more durable, and more cost-effective. The material? Wood. You read that right, folks. Wood.

Architects, builders, and people for sustainability are all buzzing over this new building material that can significantly reduce carbon emissions, pollution, and be more environmentally friendly. Did we mention the cost savings? That’s right – we did.

Timber was always readily available throughout history. If there was a gap across the river, we cut a tree down, and used it to get across. When the settlers touched down in North America, we built homes out of wood. That carried on for centuries. But when cities in North America caught on fire, such as the Great Chicago Fire of 1871, the use of lumber was then viewed as unsafe compared to concrete and steel.

But how is wood making a comeback? What’s different? The new term is “mass timber”. Basically, it’s taking pieces of soft wood such as pine, spruce, or fir, and turning them into massive (hence “mass”) pieces of timber.

Essentially, it’s creating giant wooden lego blocks.

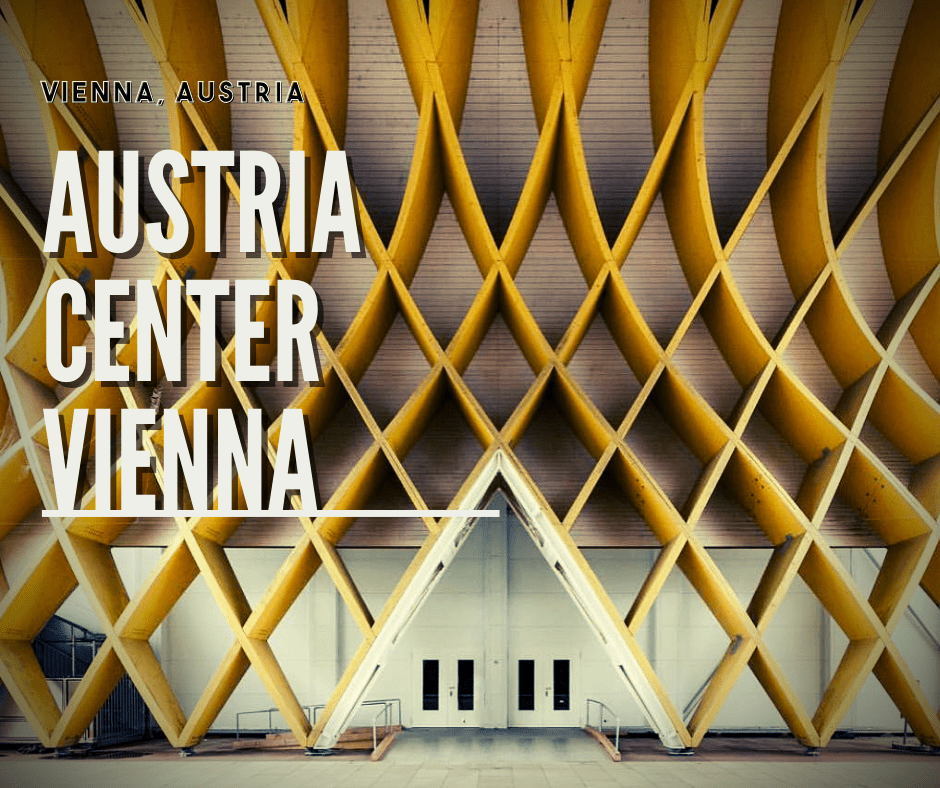

Mass timber is a fairly generic term that breaks down into a bunch of different products. There’s things like glue-laminated (glulam) beams and laminated veneer lumber (LVL), but what is really taking the world by storm is cross-laminated timber (CLT). While the trend is catching on in North America, and other places such as Australia, CLT has been popular in Europe since the early 1990’s, where it was actually developed (Austria to be exact).

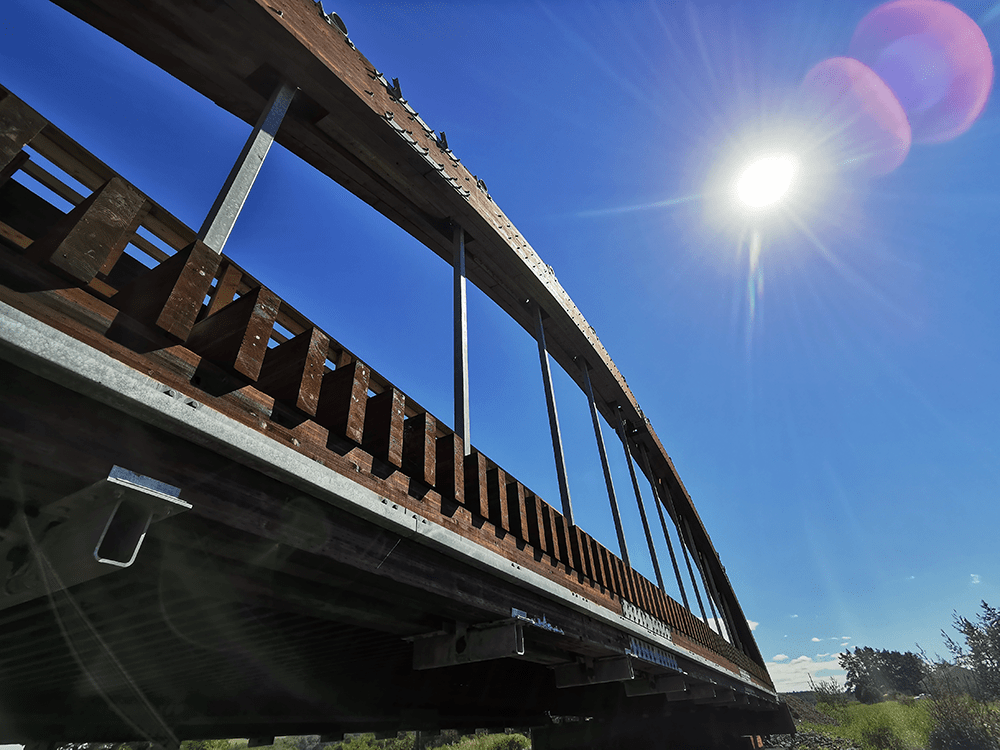

Our very own Dr. Dan Tingley was involved in the design of this project utilizing advanced high strength fibre – FiRP® Technology to get the job done.

We’re going to go over some of the benefits of mass timber, and why it’s so awesome. We narrowed the long list to only 7 of them, but there’s so much more to mass timber than these 7 points. If you’re interested in more, please get in touch with us. We love #timbertalk.

Cost savings at construction

Timber structures often have an advantage of steel and concrete structures base on initial construction costs. This is largely due to the lower self-weight and faster installation. Additionally, material costs for the timber resetoration is usually competitive with steel or concrete even before accounting for substructure and installation savings.

These advantages can be improved when designers and builders are more familiar with timber. It has been shown that contractors who are unfamiliar with timber tend to give higher bids for timber projects, compared to contractors that specialize in timber. (Moses, et al., 2017)

In a case of a rail bridge restoration project that was done in Georgia, a technician figures out where the “weakest links” would be on the structure. Some engineers would advise to destroy the whole thing. But if done correctly restored and reinforced the weakest points, and the whole project cost about $12,000, as opposed to over $135,000 and 4 weeks in time.

Carbon and environmentally friendly

Timber does not require a great deal of energy for it to be produced into a usable form, relative to other materials such as steel, which require furnaces operating at high temperatures as part of the process.

The manufacturing, transporting, and installation of building materials such as steel and concrete require a vast amount of energy. The small amount of carbon in a ton of concrete, when multiplied by the huge amount of concrete used, results in concrete being the material that contains the greatest amount of carbon in the world; especially because cement production is extremely energy and fossil fuel intensive, making it a large producer of carbon dioxide emissions contributing to global warming.

Ease of construction

Timber is light compared to other building materials, such as concrete and steel. The density of different species of wood varies can vary between 550 kg/m3 and 700 kg/m3, while concrete and steel has densities of about 2,400 kg/m3 and 7,700 kg/m3.

When using timber as a construction material, it allows design flexibility. It’s a very versatile product, with endless possibilites. Whether you’re building a large mass timber project, or framing a house, it’s relatively simple to work with. The most basic project such as making a frame, a small child can learn how to do this with simple hand tools.

Reduced cost of maintenance (compared to steel and concrete)

While it is easy to compare the initial construction cost of various material options, it is more difficult to predict the long term maintenance costs. Engineers and transportation officials are often less familiar with timber than with other materials, and there is a tendency to underestimate the lifespan and overestimate the maintenance costs for timber bridges. A 2006 study found that the maintenance cost for properly protected timber bridges is substantially lower than typically estimated (Gerold, 2006). The study evaluated over 50 modern various bridges in Germany and calculated the annual maintenance costs as a percentage of initial construction costs. Among the bridges tested, the annual maintenance costs varied from 0.1% to 2.5% of the initial construction costs. Gerold concludes that the service life and maintenance costs of timber bridges are comparable to those of steel and concrete structures. He suggests that an appropriately conservative estimate for road bridges would be 80 year service life and annual maintenance costs of 1.3% of construction costs.

Silica Contamination (when using concrete)

Silica is an extremely toxic chemical in the world. If you cut concrete with a saw, you have to have a urine test once a week to test for poisoning. According to the OSHA in the US, “Inhaling very small (“respirable”) crystalline silica particles, causes multiple diseases, including silicosis, an incurable lung disease that can lead to disability and death. Respirable crystalline silica also causes lung cancer, chronic obstructive pulmonary disease (COPD), and kidney disease.”

In many countries, to build a concrete bridge over a reservoir is no longer allowed for public safety.

Longevity

We say, “timber doesn’t last”. That’s the mantra. People often compare timber bridges that are hundreds of years old against reinforced concrete bridges that are 40 years old and say, “concrete lasts so much longer.” These old timber bridges have been giving great service for three and four times longer than the concrete bridges with poor maintenance practices and little, or no upkeep! If we treated concrete bridges the way we treat the timber bridges, who knows how short their life would be. Interesting as well that the old timber bridges that have been lasting so long were designed for significantly lower loads, yet they have continued on in service carrying much higher loads than they were built to carry. If we overloaded concrete bridges the way we overload the old timber bridges, the concrete bridges longevity would be considerably shorter than what it is now.

Scared of fire? Don’t be.

For our North American readers, we tend to associate wood in buildings with stick-frame construction, 2x4s and plywood, which are extremely flammable, and with mainstream media talking about the wildfires in California and in Oregon, it doesn’t help the case of why using timber is a much better solution. Well, here’s why:

The thing is, large, solid, compressed masses of wood are actually quite difficult to ignite. (Hold a match up to a large log some time.) In the case of fire, the outer layer of mass timber will tend to char in a predictable way that effectively self-extinguishes and shields the interior, allowing it to retain structural integrity for several hours in even intense fire.

Reports on fire testing of CLT come from the US Forest Service, the International Code Council, and the Fire Protection Research Foundation. (The Forest Service has also done extensive blast testing of CLT, which it passed with flying colors, opening the door to its use in military facilities.) The bottom line is that all building materials have to meet code, and CLT meets code for fire safety.

The Roger Bacon Bridge in Nappan, NS Canada – Photo Credit: Markoshi Baladad

Now that you’ve read up on mass timber, you’re going to see a lot more of it around. This is a big thing for the construction industry. There are so many benefits to using timber, rather than the traditional concrete and steel methods. Mass timber buildings are starting to pop in bigger cities all over the world, and they just look so aesthetically pleasing, rather than the concrete jungles we’re used to. With the cost savings during construction, and the reduced spending for maintenance, why would anyone go with another option? With the benefits above, there really is no other choice. If you know of any council or group wanting to replace or restore an olden wooden structure, TRS is fully capable of undertaking a project – all over the world. Contact us today.

References:

Gerold, M. (2006). Economic Viability of Modern Timber Bridges – Lifespan and Costs of Maintenance. IABSE Reports, 92, p. 384. Budapest.

Moses, D., Alexander, M., McAlister, K., Mesa, K., Lehan, A., Brown, S., & Dulay, G. (2017). Ontario Wood Bridge Reference Guide. North Bay, ON: Ontario Wood WORKS.