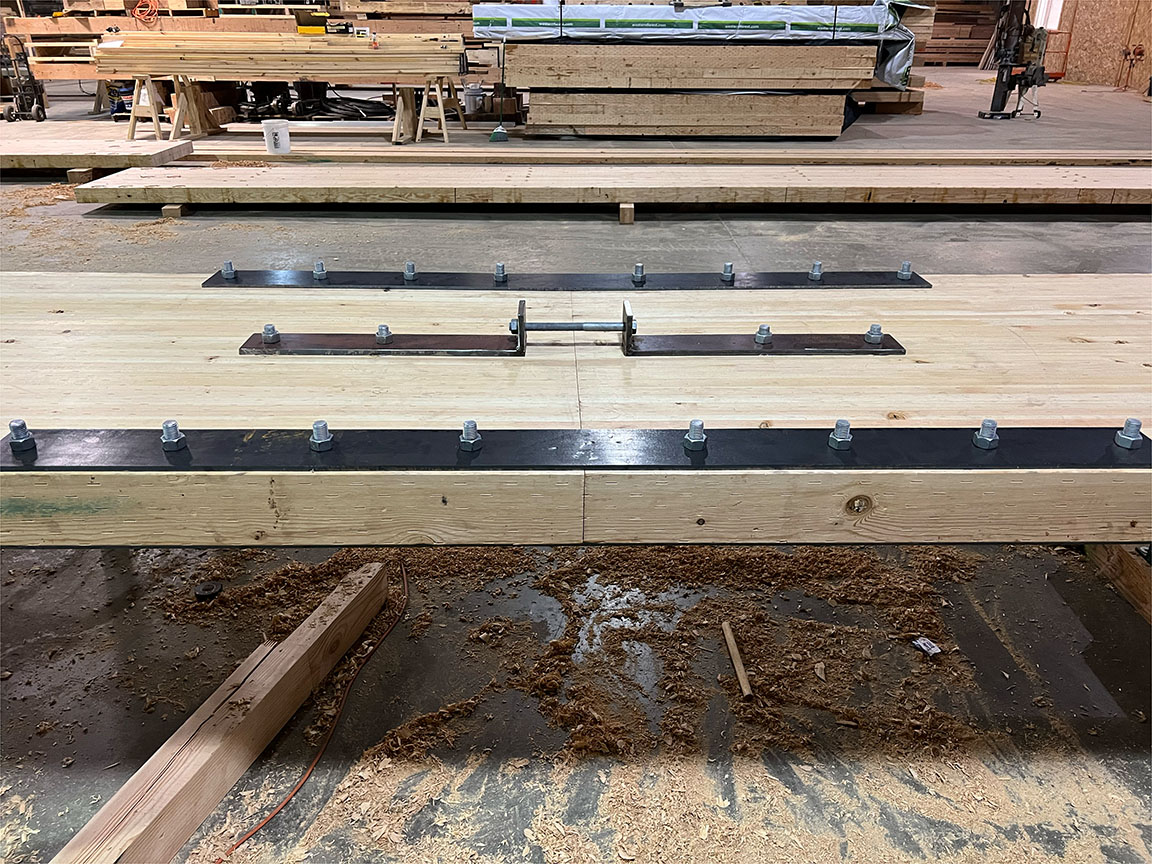

Shop Assembly

Going beyond simple shop fabrication to ensure the highest quality in everything we do.

Assembling every bolt and beam in our shop

While other builders may fabricate timber structures inside of climate-controlled manufacturing facilities, Timber Restoration Services (TRS) is one of the only firms in the world to go even further in our commitment to quality.

For new construction projects, as well as replacement components of repairs, we assemble the entire structure inside of our facilities in Oregon. This includes making every cut, placing every bolt, and drilling every hole.

the benefits of our unique shop assembly process:

- Ensures that there will be no on-site cutting, drilling, or fitting required.

- Allows us to treat the wood, while it’s assembled, so we can guarantee that we treat every exposed surface, and to double-galvanize any metals, for instance, nuts and bolts, to resist oxidation and rust.

- Empowers our experts to test the strength and load capacity of the structure, guaranteeing that it meets and exceeds your project’s requirements.

- Reduces on-site labor costs providing expedited installation and reduces structure downtime and reduces impact on communities affected.

Shop fabrication isn’t enough

When this isn’t possible, for instance, when we’re doing a part-for-part replacement on an existing structure, we treat every component, on site, to our rigorous standards, and implement our ISO 9001 quality management system on-site to ensure we’re delivering the best possible product to our clients.