Modular bridging systems became popular in the early 1990s having started with the appearance of the Doolan Deck bridge system for the repair of the Buccarumbi Bridge over the Nymboida River in northern NSW. Throughout Queensland and New South Wales, there was a proliferation of this modular bridge deck system being used for cost-effective repairs and new bridge construction. The Doolan Deck bridge system was named after Terry Doolan, the architect, and engineer of this modular system.

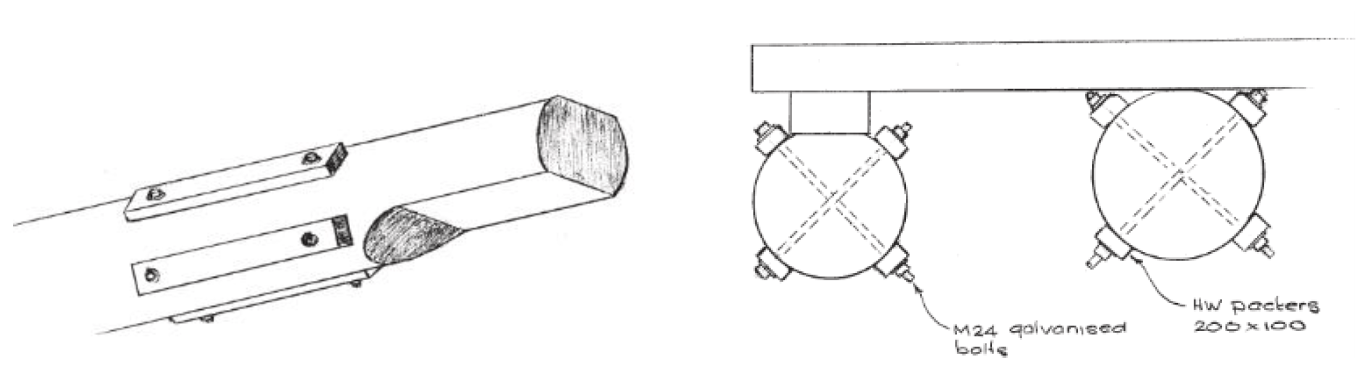

The Doolan Deck system consists of having Durability Class 1 (preferably de-sapped) low shrinkage hardwood log girders with a reinforced concrete deck integrated to the log girders through vertical fasteners and steel plates drilled/recessed into the top of the planed surface of the log girder. The engineering concept was to use the compression strength of concrete with the tensile capacity of the hardwood log girder with an interfacial connection arrangement that allowed plane sections to remain plane through the shear connection system.

The prefabricated superstructure system was made in yards and transported to the site, reducing road closure time. Many of the modular systems were designed for T44 traffic loads.

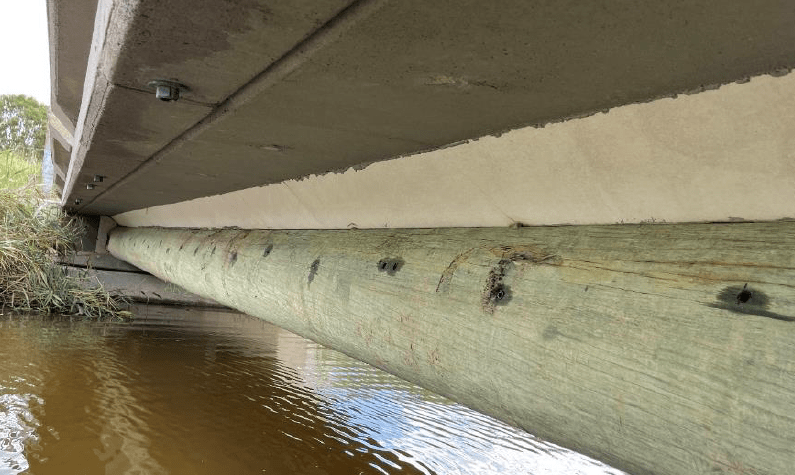

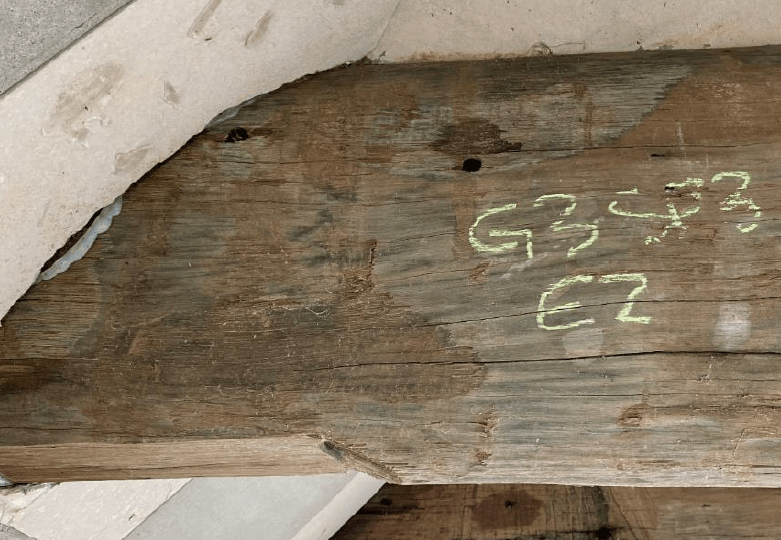

The prepared timber/concrete interface showing the shear connection

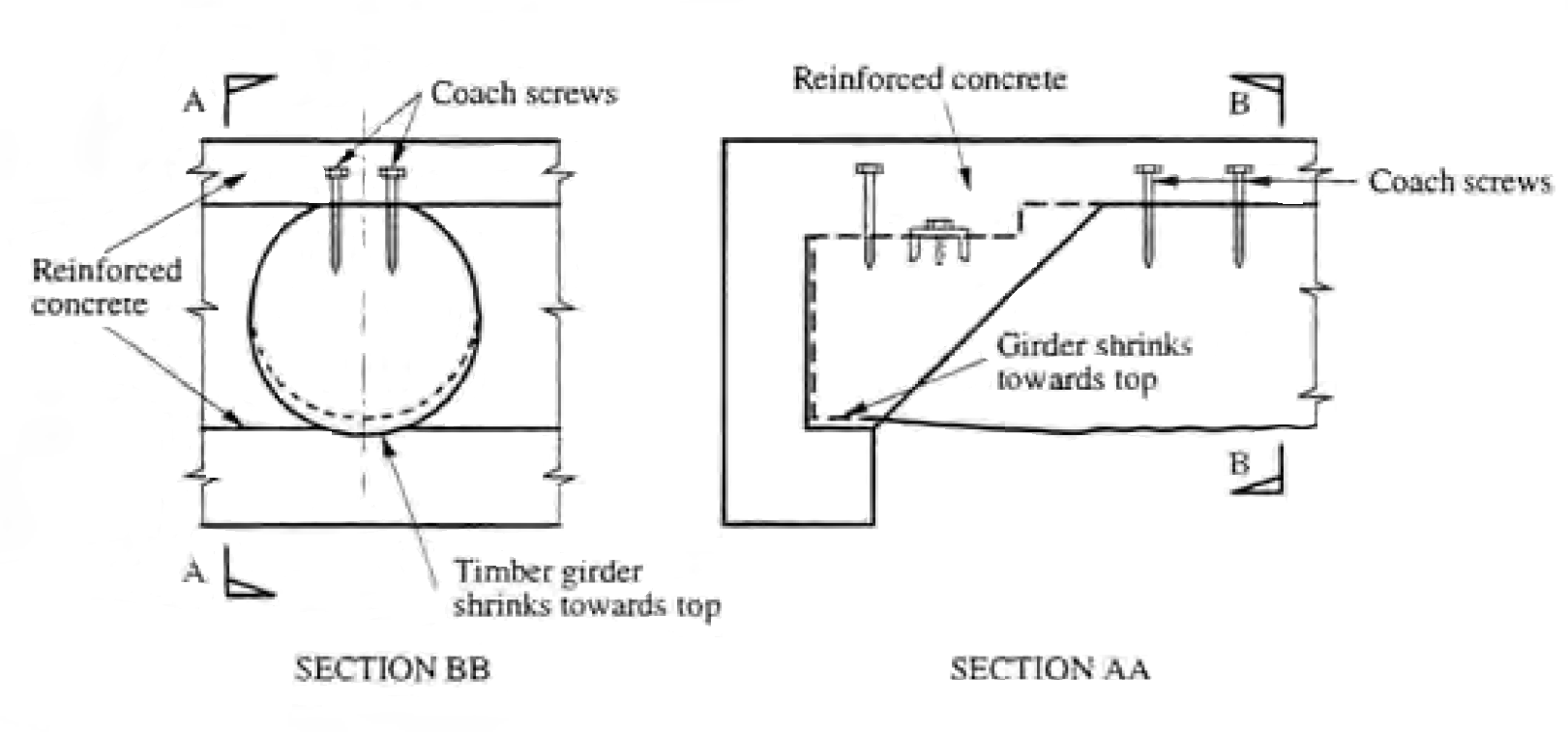

Details of the connection of the timber girder at the concrete end diaphragm.

(From “Development of A Timber/Concrete Modular System For Timber Bridge Rehabilitation”, Doolan, T.F, Carter, DJ., Roberts, W.S., Taylor, R.J., and Wheen, R.J., Bridging the Millennia, p. 347-8, 1997 Bridge Conference, Sydney, Australia, 3-5 December 1997, Conference Proceedings)

While hailed as a game changer in bridge repair and construction, fundamentally poor timber material understanding created issues that have come to the fore after years of being in situ. Over time, the concrete deck cracks, moisture ingress occurs through the concrete deck, and creates a decay zone at the concrete/timber interface – moisture barriers would only have exacerbated the problem. Since the vertical fasteners penetrate the moisture barrier, moisture from the concrete will get through (via the vertical fasteners) and become trapped on the top of the log girder.

The top half of the log girders decayed from elevated moisture content (>24%) which lead to reduced Modulus of Elasticity in compression parallel to grain and a reduction in the design composite stiffness of the system. A reduced composite stiffness causes excessive deflection in the deck/girder system, resulting in additional cracking in the concrete deck. This allows more water to enter the system from above, leading to more degradation of not only the stiffness but bending strength.

In addition, the concrete encasing of the girder ends meant moisture entrapment in the end grain causing more decay issues. Without access to the log girder ends and top surface, the degradation of these timber zones would be easily missed.

Great timber design ensures air circulation around timber elements to maintain a low relative moisture content in the timber thereby mitigating the chances for fungal decay activity. Fungal decay occurs when moisture content levels exceed 24%.

Concrete decks and concrete encapsulation allow moisture ingress and increased fungal decay activation at the concrete/timber interface with no air circulation to reduce the moisture levels.

Where Councils have sought to have bridges replaced after inspection reports state “the bridges have reached the end of their serviceable life”, the successful rehabilitation of 4 previous Doolan Deck bridges provided an alternate cost solution for the Somerset Regional Council (SRC) 2022 budget allowance.

With 17 more Doolan Deck bridges showing deteriorating concrete decks and timber issues such as notch splits and deck/girder separation, SRC engaged Timber Restoration Services to rehabilitate the bridges’ concrete decks and timber girders at a substantially lower cost than replacing the 17 bridges.

Richards Bridge

Rehabilitation Steps

There were 4 areas Council needed to address to improve the bridges’ structural integrity and long-term durability:

- Concrete attenuation to moisture ingress,

- Decay at the concrete/timber interface and girder ends notch splits,

- Notch splits,

- In situ Strengthening (separation of log girder to concrete decking)

Concrete Attenuation to Moisture Ingress

Over time, with the concrete decks exposed to movement and environmental conditions, the decks exhibited cracks throughout. These cracks allowed moisture to permeate into the concrete deck and settle against the top of the girder, creating a decay zone.

Rather than seal the concrete deck and joints with asphalt or concrete surface sealer, Timber Restoration Services engaged Markham Global to apply a penetrative treatment Aquron 7000 to the concrete decks, effectively reducing the permeability of the concrete whilst maintaining the skid resistance of the concrete surface. The application of a penetrative sealer removed the issue of a surface sealant degrading over time from traffic, sun, and movement, allowing moisture ingress.

Aquron 7000 resolved several issues demanded on the concrete protection system:

- Prevent ingress of moisture into the concrete

- Reduce the permeability of the concrete

- Penetrate deeply into the concrete

- Effectively seal cracks up to 0.5mm and not be affected by future micro-cracking

- Flexible for structural movement

- Skid resistance maintained

- Short curing time to minimise traffic disruption

- Environmentally friendly

This penetrative system, in conjunction with the bridge girders’ rehabilitation, provided a way to restore the bridge’s structural capacity and ensure the longevity of the superstructure.

Concrete deck deterioration. Note the cracked edges fo the concrete from over flexing of the log girders due to degradation in the superstructure elements

Aquron 7000 finished bridge deck ready for joint sealant replacement works

Decay – concrete/timber interface and girder end

Where the timber elements in the bridge are in hard contact with concrete, the goal is to diminish the fungal decay by reducing the moisture content in that zone. Fungal growth requires moisture content to be over 24% to maintain decay activity – reduce the moisture content, and reduce the extent of fungal decay.

When timber is encapsulated or hard against concrete surfaces without air movement to reduce the moisture content in the wood, fungal decay will occur. The difficulty in maintaining the Doolan Deck bridges is the invisibility and inaccessibility of such decay zones. The same difficulty occurs when timber poles are encapsulated with concrete sleeves – you can’t see the damage being done.

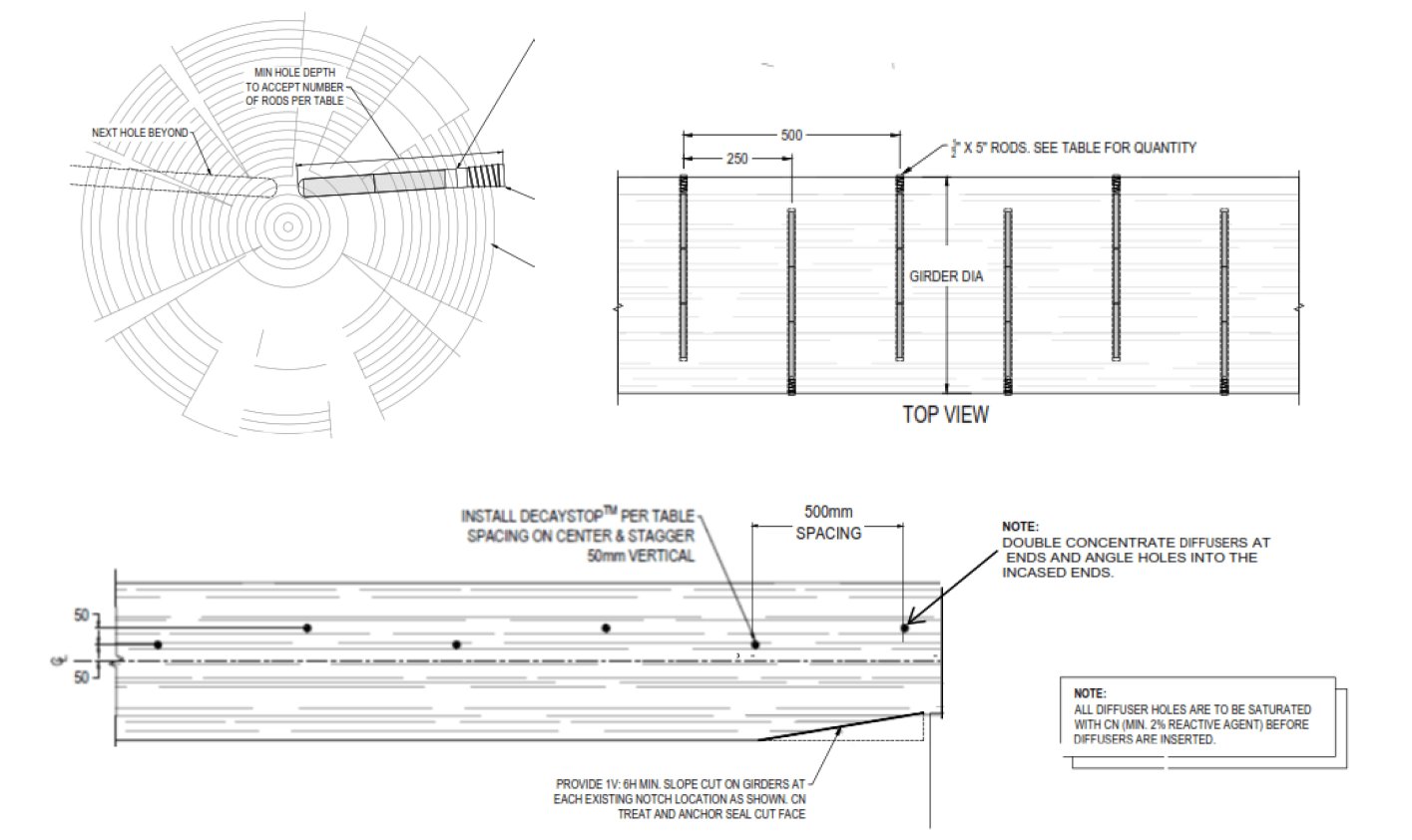

For the Doolan Deck bridges, there were 2 primary zones of decay – top surface cut and girder end. Since both zones are inaccessible, TRS installed diffusers as a means to counter fungal activity. Fungi ‘feed’ on wood by secreting an acidic wave at the leading edge of the fungal colony growth. The salt borate neutralises the acidic wave thereby stopping the fungal ‘feeding’ activity on the timber and effectively stopping decay from progressing. Diffusers are activated when the moisture content is over 20% in its vicinity.

For the Council maintenance crew, borate salt diffusers are easily checked as part of the bridge maintenance cycle or after a significant rain or flood event to see if the rods have depleted. Replacing them is an easy task of unscrewing bungs and inserting rods.

Decaystop® Diffuser pattern

Diffused log girder and girder end

Notch Splits

The common ratio of slope cuts found on timber bridges is 1:4 and whilst the Timber Bridge Maintenance Manual (TBMM) recommends a snipe slope of 1:4 (depth to length ratio), TRS has found, over the course of years attending to damaged bridges with this slope cut in place, that a 1:6 ratio mitigates this splitting event.

The notch split is caused by the rapid change in stiffness from the squared or 1:4 slope cut. This rapid change of stiffness induces tension forces being applied perpendicular to the grain (timber’s weakest resistance direction) resulting in the separation of the bottom portion from the top at the line of change. By altering the slope to the more gradual 1:6 and applying Anchorseal® to the fresh cut surface, the tension forces and moisture egress are reduced thus mitigating the chances of notch splitting.

The product Anchorseal® is a paraffin wax in water solution that reduces the rate of moisture loss from timber surfaces. Applying Anchorseal® to the end grain exposed by the 1:6 slope cut reduces the speed of end grain moisture travel, allowing it to match the speed of the side grain and reduce end checking in this zone. This occurs at the ends of timber elements due to this large differential in moisture travel in wood.

Notch split resulting from rapid change of stiffness

Notch slope (1:6) and Anchorseal® application to mitigate notch split events

Where the notch splitting is too long or big to alleviate with a new slope cut, the girder strengthening method in the TBMM (see picture below) does not stop or slow down the split from increasing along the length since it is not effectively reducing the tension forces perpendicular to the grain. In fact, this solution causes more cleavage and grain separation often leading to the creation of four separate sections in the log girder end. It is a very poor detail.

TBMM solution to excessive notch splitting

The solution that TRS has been developing over decades is removing the separated piece using a slope cut of 1:6 (reducing the rapid change of stiffness) and installing Retroten® to the underside to strengthen the reduced depth extension. The solution provided is designed and engineered by WRD.

Retroten® applied to excessive notching splitting

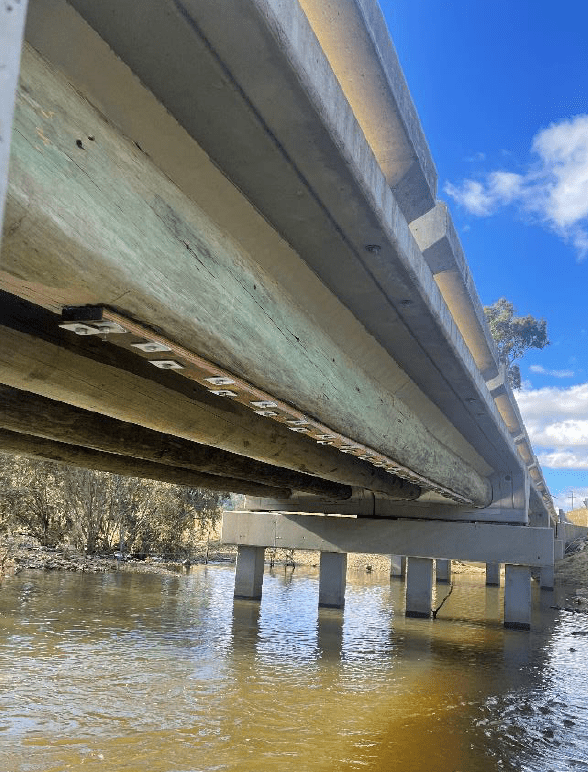

In Situ Strengthening

Through shrinkage and moisture ingress causing decay, the log girder has, in instances, separated from the concrete deck causing discrete concrete cracking.

Concrete deck separation

Terry Doolan (architect of the Doolan Deck modular system) incorrectly assumed that the engagement of the concrete deck to the timber girder would provide restraint to the top of the girder thereby ‘forcing’ the log girder to shrink upwards from the headstock (see Picture 1). The reality is that timber will shrink with the grain and for log girders, that shrinkage pattern is radial, from the outside to inside. Since the shrinkage pattern is outside to inside, the girder centroid remains in the same location.

Since the concrete was not flexible enough to follow the shrinkage pattern of the log girders, the top log surface pulled away from the concrete underside. This left gaps and caused shear translation and bearing issues. The bearing issues were particularly problematic as the gaps, resulting from the shrinkage of the log girder, provided room for the concrete deck to flex downward under its own dead load and traffic load, causing more concrete cracking.

After girders were diffused through the 17 bridges, a Level 1 inspection was performed focussing on girder defects (such as stress checks (not shrinkage checks), sloping grain, and significant knots) that could potentially affect long-term structural performance. Following Wood Research & Development (WRD) engineering analysis and instructions, Timber Restoration Services applied a Retroten® laminate to the underside of the log girder to reinforce the structural capacity of the girder. Retroten® is a polymer Aramid composite fibre bonded to the log creating a structural tension band to the log girder underside.

The use of Retroten® for these specific log girders is a fail-safe solution to the potential of bending due to stress checks caused by inherent defects.

Retroten® applied for girder strengthening

Conclusion

Prior to their rehabilitation, the Doolan Deck bridges were given a Condition State Rating (CSR) of 3 with an initial appraisal of 2-15 years maximum load limit rating.

After successfully rehabilitating 4 Doolan Deck bridges, Somerset Regional Council were able to incorporate in their budget the rehabilitation of 17 more bridges, completed within their financial year budget. All 17 bridges now have a Condition State Rating of 2 with their service life increased by another 60+ years with regular service checks as part of all good bridge maintenance regimen.

The replacement of concrete-decked timber bridges is a drastic action that is prohibitively expensive as well as disruptive to the community. There are State and Federal grants available although, the financial impost on Councils to “pony up” half the costs for bridge replacements makes for difficult asset management decisions on priority deteriorating assets with limited budgets.

The total time to fix the 17 bridges, reinstate to a CSR of 2 and increase the load rating to the desired level was 6 weeks – a fast turnaround result that no other option could fulfill. The cost of rehabilitating the log girders, fixing the concrete decks, and applying Aquron 7000 was less than $1.5 million, significantly less than any other option and finally, all the rehabilitation work was performed under traffic with minimal disruption of service.

Through the engagement of TRS & WRD services, Somerset Regional Council was able to significantly extend the service life of existing bridge assets at a low cost to the asset registry with small sink fund requirements. Replacing these bridges would incur huge financial replacement costs, large long-term sink fund requirements, and community disgruntlement over lengthy road closures.

Barney’s Rocks Bridge

England Creek Bridge

Final Project Photos

Timber Restoration Services and Wood Research & Development wish to thank Somerset Regional Council and Works Co-ordinator Peter Hardie for granting permission to publish the rehabilitation works performed on the Doolan Deck bridges in the Somerset region.

REFERENCE: Doolan, T.F., Carter, DJ., Roberts, W.S., Taylor, R.J., and Wheen, R.J.,

“Development Of A Timber/Concrete Modular System For Timber Bridge Rehabilitation”, Bridging the Millennia, 1997 Bridge Conference, Sydney, Australia, 3-5 December 1997, Conference Proceedings.