With an upsurge of national interest in the great outdoors and exercise along with Federal and State Government initiative grants, Councils are taking advantage of a fast-growing sector of the tourism industry – the rail trails.

Snowy Valley Regional Council recognised the growing trend and applied for NSW Government’s Restart NSW Regional Tourism Infrastructure fund and Stronger Communities grants. Through this funding, the 21km Tumbarumba to Rosewood Rail Trail, a walking and cycling trail that runs through a non-operational railway corridor, became the pilot for the State and a working model for future New South Wales rail trails.

Engaged by Council, timber consulting engineers, Wood Research & Development (WRD), inspected 4 neglected timber rail bridges and presented a Level 3 Inspection report with design restoration options for Council’s consideration to suit walking and cycle trail specifications. Using non-destructive testing, WRD were able to nominate elements in the existing bridges that could be salvaged and reused to retain heritage.

Undated photo of Mannus Creek bridge, when it was still an active rail bridge.

BRIDGE SPECIFICATIONS

All bridges were set to 2.5m clear travel width with a 5 kPa and 5T load rating for maintenance vehicles.

Bridge 5 (Sawpit Creek) specifications: Length 21.8m (3 spans), Height 5.3m

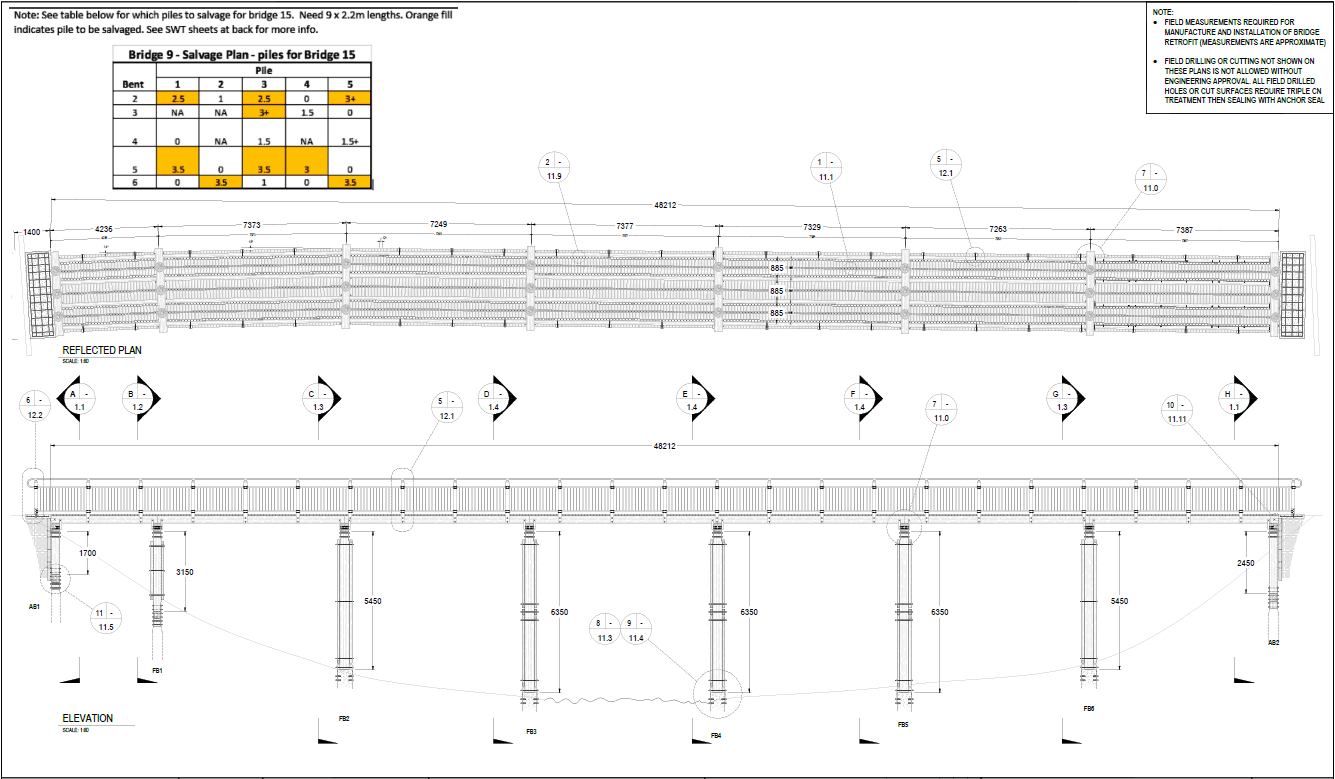

Figure 2. BRIDGE 9 (Mannus Creek)

Bridge 12 (Pigsty Creek) specifications: Length 4m (1 span), Height 3.35m

Bridge 15 (Bells Creek) specifications: Length 21.5m (5 spans), Height 3.3m

Timber Restoration Systems (TRS) won the Design & Construct tender to restore and convert these grand old rail bridges into serviceable pedestrian and cycling bridges for outdoor hiking and riding.

With 2 crews of 3, TRS attacked the project in late November 2019, but by December, the work had to be deferred while the bushfires raged and devastated the surrounding Tumbarumba region. Thick choking smoke and the proximity of the fires halted work for the crews to return to Brisbane and out of harm’s way. The project recommenced in early February after rains brought relief to the ravaged region.

For this blog, we will examine the dismantlement and construction of Bridge 9 at Mannus Creek. Keep coming back to this blog as we do the other 3 bridges over time.

BRIDGE 9 (MANNUS CREEK)

Bridge 9 is the grand old lady, the queen of the Tumbarumba bridges – the longest and tallest timber bridge of the four. With a length of 48.2m, 7 spans, nearly 7m tall and slightly curved, Bridge 9 presented the biggest challenge and provided the most spectacular outcome.

As with each bridge in the project, full length and height scaffolding was erected to provide a safe working platform for the crew. All timber cuts including pile stubs were sealed with Copper Naphthenate(CN) oil and Anchorseal®, a paraffin-based sealant. All drill holes were squirted with CN oil prior to be connected.

With scaffolding up, a crane pad was laid down alongside the bridge to carry a 100 tonne mobile crane. Prior to the crane arrival, TRS disconnected most of the elements (whilst maintaining structural stability), ready for dismantling.

Within 2 days, the bridge was dismantled with the 100 tonne crane lifting complete bents out and laying them out in the adjacent paddock. Once lain, the bents could be broken down, elements tested using the non-destructive testing (Stress Wave Timer) equipment and sorted for reuse.

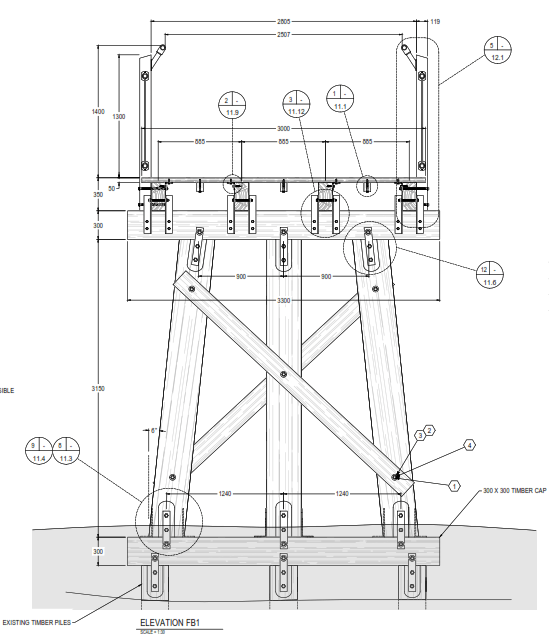

BRIDGE 9 dismantlement

In lieu of replacing the piles at the abutments and bents, TRS reuse the existing bent and abutment piles that are buried in the soil. Depending on the porosity of the soil, timber piles in undisturbed ground will generally be preserved from approximately 400 mm below the ground level. With 400mm and deeper undisturbed ground, oxygen generally does not reach the timber pile thereby starving fungi, eliminating decomposition. Once the ground is excavated around the pile, TRS engages the Stress Wave Timer and assess the timber quality for pile-posting. In some cases though, the excavation needed to be down 1m before solid good foundation wood quality was found.

All the bents for the abutments and piers were prefabricated in the compound, ready to be transported, lifted and installed into position. This method is far easier to set out and work on with these large heavy bridge elements (300×300 headstocks, 300-350 diameter poles and 100×200 cross braces) using a telehandler or franna.

With the abutment piers in place, the set out for the remaining bents was marked up and a 100T mobile crane was brought in for the big lift. Each new bent weighed over 5 tonnes with the longest lift radius being the 40m. Due to the curve in the bridge, the pier bents were lifted without the headstocks in place allowing for them to be placed with the crane and cut once in position to accommodate the changing position. All cuts were sealed with Copper Naphthenate oil and Anchorseal®.

The deck panels were prefabricated in the compound for lifting into place onto the rectangular girders. Angle brackets were attached to the girders to lock the deck panels down from underneath. Having no exposed fixings on the deck, the bridge deck lasts longer and the ride is so much smoother.

The work done on Bridge 9 was simple in its methodology – prefabricate as much as possible on the ground and lift into position. Taking this approach, the bridge height was essentially negated as a difficulty factor. The work was performed at a much safer and quicker rate using mobile equipment such as a telehandler or franna to manoeuvre heavy elements on the ground. However, as a precursor to implementing this method, time must be allowed to fully survey the existing bridge, continually survey the bridge as it is installed and update construction plans as this data becomes available. These tasks are exacting but the reward for rigorous planning is a safe and faster construction process especially with such large cumbersome bridge timber elements.

With timber posts, galvanised cycle rail and balustrading and a blemish-free deck, this 48m long bridge is the pinnacle of the rail trail where cyclists and hikers can venture under the bridge to inspect her grandeur. The Tumbarumba-Rosewood Rail Trail is certainly a great example where the old ladies of the railroad lines can once again shine in the spotlight.