Wagga Wagga City Council launched the Wiradjuri Trail Master Plan in August 2021, setting out a 10-year improvement blueprint that includes more than $6 million worth of proposed development. The aim is to “connect the local community and environment, highlight places of significance to the Wiradjuri and First Nations peoples, and transform the trail into a major tourism asset that will benefit our local economy”.

The Flowerdale Lagoon pedestrian footbridge was one of three high-priority projects identified for the popular 42 km walking track that surrounds the city.

The original Flowerdale lagoon bridge to be replaced as a part of council project.

What Was Wagga Wagga Council Looking For?

Wagga Wagga City Council wanted the existing narrow footbridge removed and replaced with the new footbridge in the same alignment and fitting into the existing track, maintaining the same girder soffit RL. Council wanted a bridge that was congruous with the tree-lined anabranch, environmentally and indigenous friendly, in color and shape. With Flowerdale Lagoon often chosen for wedding backgrounds, Council wanted a standout bridge for cyclists, pedestrians and patrons to share.

Promoting a sustainable, pre-machined, pre-assembled, specially treated engineered glulam timber structure that has a design life of 100 years with little to no maintenance, Council felt the right combination of aesthetics, materials and functionality was in the Timber Rrestoration Services (TRS) proposal. Being ISO 9000 accredited, Timber Restoration Services provides a quality assured timber structure that Council can have confidence in its long term performance.

The treated engineered glulam side girder superstructure configuration brought together a package of strength, curvature and natural elegance that blended well in the bushland environment of the Flowerdale precinct. The angled handrail and balustrade design naturally guides cyclists to not ride close to balustrading, preventing their pedals from being caught. A timber top rail of dressed 200×100 hardwood softens the visual presence of galvanised steel posts and balustrading whilst providing a warm natural texture as pedestrians walk along the bridge

Treated Engineered Glulam Side Girders with FRP mesh grating.

So why choose treated engineered glulam over other products?

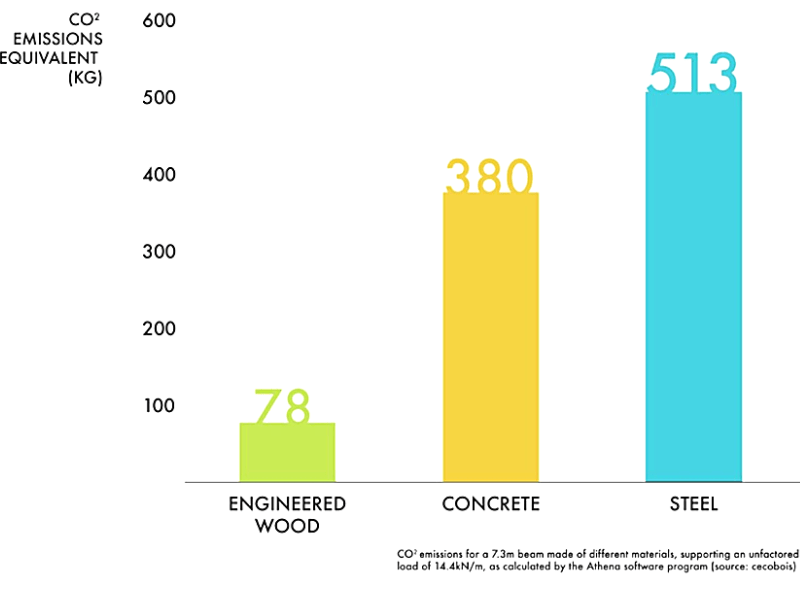

Environmentally, timber has a smaller carbon footprint than reinforced concrete, aluminium, steel and composite fibre. Once the timber has been cut and treated, the carbon the trees have absorbed during their growth, remains locked in. Plantation timber is a fast-growing renewable resource and with specialty preservative treatment, will last for 100+ years with a regular maintenance regime.

.

Extracted from “Addressing Embodied Energy with Mass Timber”, S.Zakrzewski & A. Gray

(https://passivehouseaccelerator.com/articles/addressing-embodied-energy-with-mass-timber)

Mass timber, such as engineered glulam, is without question, a highly sustainable product because it requires much less energy to produce than comparable materials, can be recycled without massive energy input and, it sequesters carbon in its fibres. If it is harvested properly, it is renewable and does not degrade forest ecosystems. Beyond its sustainability benefits, it is also dimensionally stable and allows for precise manufacturing, prefabrication, and quick construction.

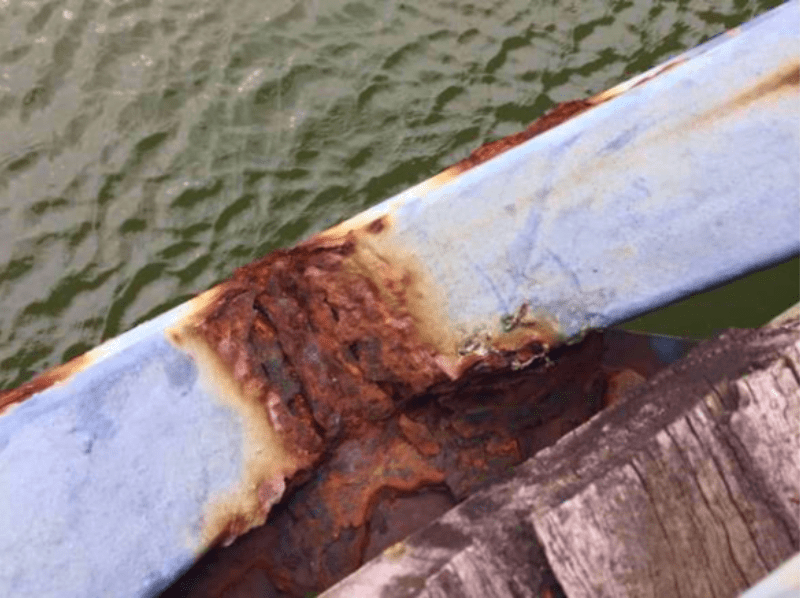

Concrete and steel require ongoing regular maintenance particularly for lightweight construction such as footbridges where steel box section trusses and thin concrete slabs are regularly used. Without durable treatments and maintenance, these products will suffer the consequences of moisture penetration, moisture entrapment and corrosion. Hot-dipped galvanising will require major maintenance within 25 years. The treated preservative glulam that Timber Restoration Services uses requires no coat maintenance.

Timber Restoration Services uses specially preservative treated glulam beams for its bridges that are not available in Australia but is approved by the Australian Pests and Veterinary Medicines Authority. This heavy oil based preservative treatment doesn’t leach and will provide the durability required from termite and fungal attack. With substantiated durability tests from the swamps of Louisiana, TRS has the evidence to ratify the 100 year design lifealong with good design and construction practices.

Aesthetically, the natural beauty of timber bridges, nestled in idyllic environments where patrons want to walk and exercise, resonates with local and indigenous communities. Council concerns of high maintenance and long term durability are nullified through good design and good construction and durable material selection. So why not choose treated engineered glulam over other products?

Prefabrication

Once the WRD design drawings were finalised and approved by Wagga Wagga City Council, the glulam fabrication shop in Jefferson, Oregon began fabricating the components. Once fabricated and quality checked, the bridge was assembled, then disassembled and sent to the treatment plant.

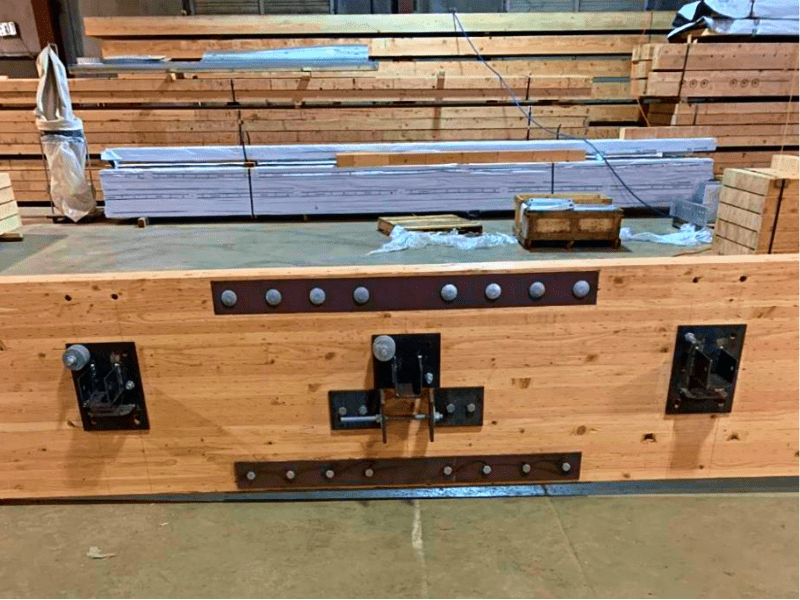

With Timber Restoration Services having ISO accreditation, the ISO quality audit before treatment is an important step in achieving the quality standards expected by the clients. Pre-fabricating the glulam components with holes drilled before treatment means that the special preservative treatment can coat all

Connections are pre-assembled in our plant in Jefferson, Oregon.

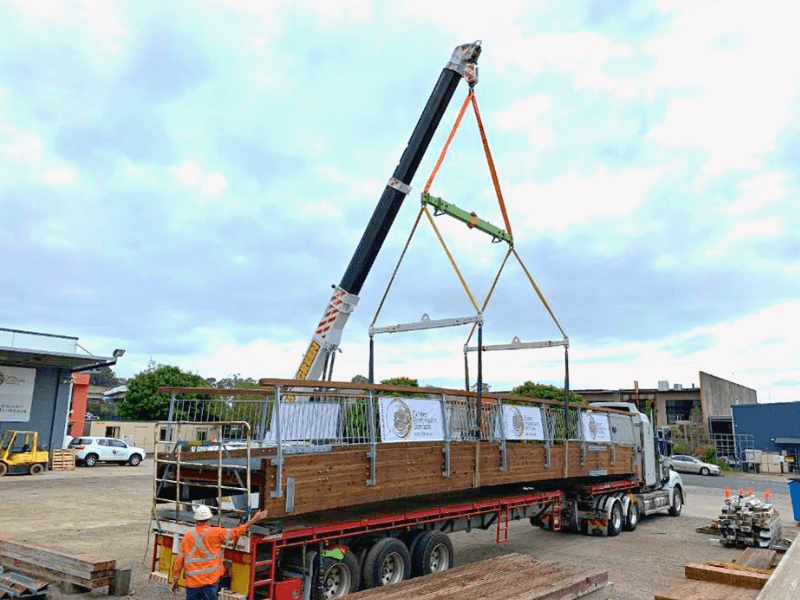

The benefit of this method is the quick assembly and construction time. The treated engineered glulam elements are prefabricated, assembled and disassembled in the workshop prior to being shipped from the US. Once in TRS’ Queensland yard, the timber structure was then assembled including the FRP mesh decking and balustrading for a final quality audit and ready for transport to site as a complete unit.

A true benefit of treated engineered glulam is that being lightweight, smaller more economical cranes can be used to lift completed treated engineered glulam bridges into position.

This “IKEA” system of bridge building means that there is greater precision and quality control, minimizing of waste on site and errors being made. With Timber Restoration Services gaining ISO accreditation, this is an important step in achieving the quality audits in place.

Construction

Being recognised as one of nine culturally significant Aboriginal sites around Wagga Wagga, Wiradjuri elder Uncle James Ingram carried out a cultural assessment to check for First Nations artefacts. Wagga Wagga City Council engaged a Wiradjuri community member with cultural knowledge to monitor excavation works and advise on any finds. As an additional measure, TRS personnel and its subcontractors were required to undertake cultural awareness training conducted by a local Wiradjuri person.

With poor foundation soil quality (silty alluvial clay) and difficult site access for heavy machinery, TRS opted for screw piers as the means to achieve bearing capacity and lateral resistance for the abutments. 2off 178mm dia.x 8.4mm wall thickness screw piers were screwed under each abutment to a depth of 6m. The heads of the screw piers were then integrated into a concrete pile cap and backwall. Since the site had strict environmental caveats, limiting tree lopping and clearing, the 8T screw piling excavator was able to easily manoeuvre in position without disturbing tree overhangs.

TRS crews screw piling along banks

Once screw piling was completed, the concrete abutments were formed, inspected, poured on site and left for curing, ready for the bridge.

Flooded abutments

However, a week after the concrete abutments were formed and poured, the site flooded and with ongoing intermittent rain, the bridge installation was delayed. The wet ground conditions from rains and flooding made life difficult in addition to the site’s awkward position made the installation a challenging process.

Coming in from above

Due to its strict environmental caveat, placing a crane close to the bridge site to lift the bridge in was not possible. A 100 tonne capacity All Terrain mobile crane with a reach of 52m was brought in to lift the 4.8 tonne footbridge directly off the truck, raise it over the tall gum trees that lined the lagoon, before lowering it onto the new concrete abutments.

Compaction of the gravel footpath

Wagga Wagga City Council’s parks and recreation assets officer Rob Owers said, “The footbridge will provide a safe, all-inclusive crossing of the Flowerdale Lagoon, making walking and riding the trail easy and enjoyable for families and other users. It will increase access for people of all abilities and will also enable cyclists to use this section of the Wiradjuri Trail.”

Mother Nature’s first test

A few weeks post project completion weeks, Flowerdale Lagoon’s newest attraction was subjected to the flooding waters of the Murrumbidgee River and passed its first test of endurance with flying colors. The Murrumbidgee River at Wagga Wagga peaked at 9.72 meters, causing major flooding in the city for the first time in a decade. The flood waters rose well above the footbridge cycle rail height which is set at 1.4m above the deck level.

After this event, Timber Restoration Services can confidently say to Mother Nature … “Bring it!”

The Flowerdale Lagoon footbridge, just a few days after flooding in the area subsided.

The Flowerdale Lagoon footbridge, just a few days after flooding in the area subsided.

Regardless of setbacks encountered due to weather and environmental factors. TRS was able to get the bridge installed that will last 100 years and bring great aesthetic value to the Wiradjuri walking Trail. Timber Restoration Services would like to thank the Waga Waga City council for the trust given to us to execute this amazing project. We look forward to working with them potentially in the future on many projects.